DANGER:

CONTACT WITH HARDENER MAY CAUSE PERMANENT EYE DAMAGE. MAY BE HARMFUL BY SKIN CONTACT OR BREATHING VAPORS OR MISTS. CONTACT WITH RESIN MAY PRODUCE ALLERGIC REACTION BY INGESTION, INHALATION OR SKIN CONTACT. CONTACT MAY CAUSE EYE/SKIN IRRITATION.

PRECAUTIONS:Avoid inhalation, ingestion, eye and skin contact. Wear protective gloves and goggles. Use window exhaust fan or other suitable equipment for a well ventilated work area. Keep container tightly closed when not in use.

KEEP OUT OF THE REACH OF CHILDREN.

Hardener Contains:Nonyl Phenol, Polyoxyalkleneamines and N-Aminoethylpiperazin.

Resin Contains:A/epichlorohydrin resin and aliphatic and aromatic glycidyl ethers. Contact a poison control center for more health information. FIRST AID: ORAL: If resin is swallowed, induce vomiting. If hardener is swallowed, do not induce vomiting. CALL PHYSICIAN IMMEDIATELY! EYES: Severe irritant to eyes. In case of eye contact, flush thoroughly with water for 15 minutes and get prompt medical attention. SKIN: Wash immediately with soap and rinse thoroughly with water. Do not use solvents or alcohol to remove product from skin. INHALATION: Move to fresh air. If not breathing, administer CPR. If breathing is difficult, get medical attention.

PREPARATION. Some things to know before using Envirotex Lite®: IT IS MOST IMPORTANT THAT BOTH RESIN AND HARDENER ARE THOROUGHLY "WHIPPED" TOGETHER IN A FLAT WALLED AND FLAT BOTTOMED CONTAINER WITH A FLAT SIDED STIR STICK. SIDES AND BOTTOM OF CONTAINER MUST BE SCRAPED WHILE MIXING. PRODUCT WILL NOT CURE PROPERLY AND WILL BE SOFT OR STICKY IF MIXING DIRECTIONS ARE NOT CAREFULLY FOLLOWED-READ DIRECTIONS CAREFULLY. Envirotex Lite is a reactive polymer compound. It cures to a thick, glossy coating in about 8 hours at 70 degrees F, and reaches full strength and toughness in about 72 hours. This durable, resilient material requires no polishing to produce a high gloss. One coat is all that is usually required for a deep attractive finish, however, two or more coats may be applied one over the other by simply wiping the surface with alcohol prior to recoating.

ENVIROTEX LITE IS NOT RECOMMENDED FOR EXTERIOR USE. TO COAT OVER POLYURETHANE FINISHES, SCUFF SAND AND WIPE CLEAN PRIOR TO COATING.

Coverage.

4 OZ. KIT. ................... 1 square foot

8 OZ. KIT. .................... 2 square feet

PINT KIT. .................... 4 square feet

QUART KIT. ............... 8 square feet

1/2 GALLON KIT. ..... 16 square feet

GALLON KIT. ........... 32 square feet

APPLICATION:

Before starting projects, see additional information under Creative Ideas and Techniques

1. Measure. In the same graduated container ![]()

2. Mix.

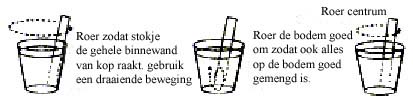

Mix the measured resin and hardener in a clean container. Stir until the material is thoroughly blended. Mixing should be completed after 2 minutes of vigorous mixing. The importance of thorough mixing cannot be over-emphasized. The two components must be whipped much like mixing a cake batter. If bubbles get whipped into the mixture, do not be concerned; the bubbles can be easily removed later. Improper mixing can result in soft or sticky spots.

To prevent problems with improper mixing, we suggest using a "double-cup" method of mixing: have two mixing containers ready. Begin mixing in the first clean mixing container. After one minute of mixing, transfer the Envirotex Lite into the second container and continue mixing for one minute. Mixing should be completed after two minutes of vigorous mixing.

3. Pour, Do Not Wait!

Pour as soon as thoroughly mixed. Carefully pour over the surface in an even pattern. Spread where necessary using a piece of stiff paper to help liquid flow together. Caution: It Envirotex Lite is left in mixing container, it will become hot and set up rapidly.4. De-gas. After about 5 minutes, the air bubbles created while stirring will rise to the surface. They can be easily and effectively broken by GENTLY exhaling on them until they disappear (avoid inhaling fumes). A propane torch can be used as an aid in removing bubbles from a freshly coated surface. Hold the torch about 6 inches away and sweep smoothly across the surface until the bubbles are gone. Use low flame. This process may be repeated as often as is necessary while material is liquid. Brush edges until material has set" firm enough not to "sag." NOTE: It is carbon dioxide, not heat, which breaks up the bubbles

5. Cure. For best results, coat at temperatures between 70° F and 80° F . Allow the coated item to cure in a warm dust free room. Curing time will vary with humidity and temperature. Humidity below 50% is recommended for proper hardness of film. Placing a clean cardboard box over the item is effective in keeping dust off the surface during the cure cycle.

Temperature

Dust Free

Hard Cure

70° F

80° F

90° F

4-7 hours

3-6 hours

2-5 hours

72 hours

48 hours

36 hours

6. Clean-up.

While liquid, the material can be cleaned up with alcohol. After it has cured, it can only be removed by long exposure to epoxy stripper, sanding or infrared paint peeler.Bubbles.

One of the important signs that you are mixing Envirotex Lite well enough is the appearance of bubbles while you are mixing. This is normal. Envirotex Lite has been specially formulated to de-gas itself, freeing most bubbles, automatically. Occasionally, however, bubbles will become trapped in the surface. They can be easily removed by exhaling your breath gently over the surface, or by carefully sweeping a propane torch across the liquid at a height of approximately 6-8 inches.

Torching.

As mentioned above, torching is a method for releasing bubbles from a pour that may not de-gas itself. Care should be taken to avoid over torching. If wooden objects are not sufficiently seal coated prior to torching, the torching will cause wood to "bleed" air into a fresh coat of Envirotex Lite, and these bubbles are difficult to stop. The torch should never be held in one place, as this will permanently damage surface and coating. Use a swift, even sweeping motion when torching and never hold torch closer than 6 inches from surface

Tools Required:Envirotex graduated cups, stir sticks and brushes are available. The mixing containers must have smooth, flat walls and a flat bottom. The stir stick must have a straight edge (like a paint paddle) to allow the user to scrape sides and bottom of mixing container thoroughly while mixing. The brush is used to coat edges and to pick up drips from the work surface covering to brush on areas at the edges missed during pouring.

Surface: Coverage will vary according to surface and method of application. The surface to which Envirotex Lite is to be applied should be dry and free from dust, grease, wax or oil. Level the surface. The surface should be up off the work area about 2 inches to allow the coating to drip freely off the sides of the item being coated. Put plastic sheeting, wax paper or multiple layers of newspaper underneath the item being coated to catch drips. See "Seal Coats' on back. The unique self-leveling qualities of Envirotex Lite can be attained only by using enough material to flood the surface. It is better to mix a little too much, rather than too little. Mix only as much Envirotex Lite as you can pour and spread at one time. Unmixed components should remain in original containers. After pouring you have about 25 minutes working time before Envirotex Lite begins to harden.