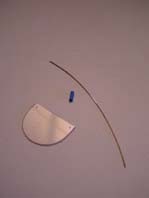

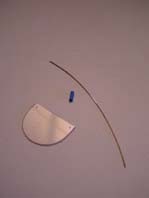

First you need to determine how big the trolling rudder needs to be. A rudder needs to be at least half the size of the used spinnerblade. If you are going to use aluminum you will need to cut the ruddershape with a metall scissor. After that the rudder edges need to be filed in order to remove any sharpnes. When you don't do this you can damage your line, yourself or the fish. It is easer and better to use a plastic rudder. They are easy to cut and are never sharp. The plastic exists of two layers that are glued together, wich make it unbreakeble. This plastic is sold under the name Vikonyl.

First you need to determine how big the trolling rudder needs to be. A rudder needs to be at least half the size of the used spinnerblade. If you are going to use aluminum you will need to cut the ruddershape with a metall scissor. After that the rudder edges need to be filed in order to remove any sharpnes. When you don't do this you can damage your line, yourself or the fish. It is easer and better to use a plastic rudder. They are easy to cut and are never sharp. The plastic exists of two layers that are glued together, wich make it unbreakeble. This plastic is sold under the name Vikonyl.

As shape of the rudder it's best to take a halve circel. This shape will take less dirt on it when fished. When you have cut the rudder you need to will have to drill the holes in it. If you use plastic you can also do this by using a hot needle or a heated piece of metall wire. Remember to use the right diameter for the holes, regarding the steel wire you are going to use for the trolling rudder. When you have drilled the holes, at approximately 2 mm from the side (from the side and from the straight side), you can move on and begin making the axle.

Take the wire (of the correct length) in a pair of roundnosed pliers, at aproximately 1cm to 1,5 cm from the end. Take the wire in your left hand, so that the long end goes trough your hand. Turn the pliers away from you and while you hold the wire firmly, turn the wire untill the pliers bounce. Now use your left thumb as a counterweight and push a little harder in order to get a nice indentation in the semi-circular shape. Then you turn the wire 180° round the axis and repeat this.

Take the wire (of the correct length) in a pair of roundnosed pliers, at aproximately 1cm to 1,5 cm from the end. Take the wire in your left hand, so that the long end goes trough your hand. Turn the pliers away from you and while you hold the wire firmly, turn the wire untill the pliers bounce. Now use your left thumb as a counterweight and push a little harder in order to get a nice indentation in the semi-circular shape. Then you turn the wire 180° round the axis and repeat this.

This wil get you (after practising a few times) a nice round eye.

When you have bent a nice eye, put the eye in a vice and let the small piece of wire point up.

With the help of a pair of combination-pliers you can wrap the small piece of wire around the long one.

When you have bent a nice eye, put the eye in a vice and let the small piece of wire point up.

With the help of a pair of combination-pliers you can wrap the small piece of wire around the long one.

Sometimes it can be necessary to finish the wrapping with the combination-pliers. To do so, put the pliers on the wrapping and turn, while you squeeze firmly, in the direction of the wrapping. If you wish, you can file of any points that stick out. The wrapping should at least have two wrappings next to eachother.

In order to finish the eye completely, slide a piece of heat shrinking tube over the wrapping. Put the lighter under it for just a moment and the tube will shrink nicely around the wrapping. Pay attention that the shrinking ability of the tube is sufficient, regarding the thickness of the wire you used. You have just finished the eye on your trolling rudder axle.

Than you take the axle at 5-7 mm from the eye in the combination pliers, so that the eye is flat regarding to the point of the pliers. You make a fold in the wire of the thickness of the used rudder.

You do this by bending the wire for 90 degree and then repeat this after moving the pliers towards the end of the wire for the thickness of the rudder.

After that you put the axle in one of the holes of the rudder. Just until the rudder falls over the bend.

Now you take the axle and hold it against the rudder. Take the wire in the middle of the second hole and give it a 90 degree bend towards the rudder.

Put the bended wire in the second hole and bend it again. You can't avoid the wire to bend lightly. But that's just a good thing, because the tension will make sure that the rudder is nice and tightly. And can't go wobble around.

Than you take the eye of the trolling rudder between your thumb and pointfinger and hold it tight. Determine the place of the eye by taking the half of the piece of wire that is left in the roundnose pliers.

Then you start to make another eye like discribed before. Make sure that the eye is in one line with the first eye. Only to make sure that the single strand leader and the spinner are standing correctly behind the trolling rudder.

Then you start to make another eye like discribed before. Make sure that the eye is in one line with the first eye. Only to make sure that the single strand leader and the spinner are standing correctly behind the trolling rudder.

Now you have a nice long piece of wire sticking out. Take a pair of combination-pliers and put the end in the pliers over a length of 3 to 4 mm and turn it over in a single bend. The existing hook is again taken with a combination-pliers and then turned towards the axis of the single strand leader. The snap-lock is finished.

Don't make the snap-lock too large. This will only diminish the spring effect. As an indication the snap-lock should be 1.5 to 2 cm from the end. Always use stainless steel wire of at least 0.6 mm thick.

And the trolling rudder is ready. Preferably use stainless steel wire of 0.7 mm dik. It is wise to cut the wire a little bigger the first few times. Otherwise you can get problems when bending the snaplock.

Source: Snoek van klein tot groot en Poask Hengelsport

First you need to determine how big the trolling rudder needs to be. A rudder needs to be at least half the size of the used spinnerblade. If you are going to use aluminum you will need to cut the ruddershape with a metall scissor. After that the rudder edges need to be filed in order to remove any sharpnes. When you don't do this you can damage your line, yourself or the fish. It is easer and better to use a plastic rudder. They are easy to cut and are never sharp. The plastic exists of two layers that are glued together, wich make it unbreakeble. This plastic is sold under the name Vikonyl.

First you need to determine how big the trolling rudder needs to be. A rudder needs to be at least half the size of the used spinnerblade. If you are going to use aluminum you will need to cut the ruddershape with a metall scissor. After that the rudder edges need to be filed in order to remove any sharpnes. When you don't do this you can damage your line, yourself or the fish. It is easer and better to use a plastic rudder. They are easy to cut and are never sharp. The plastic exists of two layers that are glued together, wich make it unbreakeble. This plastic is sold under the name Vikonyl.

Take the wire (of the correct length) in a pair of roundnosed pliers, at aproximately 1cm to 1,5 cm from the end. Take the wire in your left hand, so that the long end goes trough your hand. Turn the pliers away from you and while you hold the wire firmly, turn the wire untill the pliers bounce. Now use your left thumb as a counterweight and push a little harder in order to get a nice indentation in the semi-circular shape. Then you turn the wire 180° round the axis and repeat this.

Take the wire (of the correct length) in a pair of roundnosed pliers, at aproximately 1cm to 1,5 cm from the end. Take the wire in your left hand, so that the long end goes trough your hand. Turn the pliers away from you and while you hold the wire firmly, turn the wire untill the pliers bounce. Now use your left thumb as a counterweight and push a little harder in order to get a nice indentation in the semi-circular shape. Then you turn the wire 180° round the axis and repeat this.

When you have bent a nice eye, put the eye in a vice and let the small piece of wire point up.

With the help of a pair of combination-pliers you can wrap the small piece of wire around the long one.

When you have bent a nice eye, put the eye in a vice and let the small piece of wire point up.

With the help of a pair of combination-pliers you can wrap the small piece of wire around the long one.

Then you start to make another eye like discribed before. Make sure that the eye is in one line with the first eye. Only to make sure that the single strand leader and the spinner are standing correctly behind the trolling rudder.

Then you start to make another eye like discribed before. Make sure that the eye is in one line with the first eye. Only to make sure that the single strand leader and the spinner are standing correctly behind the trolling rudder.